-

Location:

- Home

- > news center > cooperative R & D

In my country's capacitor market, the proportion of traditional aluminum electrolytic capacitors is declining, followed by more advanced and more environmentally friendly new capacitors gradually on the stage of the times-film capacitors.

Since the beginning of the development of the capacitor industry in the 1980s, to the current continuous expansion of the capacitor industry, my country's capacitor industry has developed rapidly, attracting enthusiastic investment from foreign investors, and to this day, the capacitor industry is still heading forward. After more than 20 years of continuous exploration and experimentation, thin film capacitor technology has become increasingly mature, which has brought new development opportunities to some emerging products, such as solar vehicles, electric vehicles, and energy storage welding machines.

Film capacitor leads the field of energy storage welding machine

In the field of energy storage welding machine, the capacitor energy storage welding machine uses the power frequency alternating current to charge the capacitor after being rectified by the rectifier. The stored electric energy is then discharged by the welding transformer and converted into a low-voltage, relatively concentrated and stable pulse current. The contact point of the welding workpiece generates resistance heat, thereby welding the metal. Therefore, capacitors occupy a large proportion of energy storage machines. At present, the mainstream energy storage welding machines in the market are basically aluminum electrolytic capacitors, and the service life of aluminum electrolytic capacitors is generally not high. Foreign aluminum electrolytic capacitors such as The service life of Heigang, Sunli, Ruby, etc. is about 5-6 years. Domestic capacitors generally have a service life of 1-2 years. Therefore, in the field of energy storage welding machines, foreign Heigang capacitors are still used. . However, foreign capacitors basically have slow supply, long order time, and high prices, so maintenance and inventory increase the operating costs of SMEs. It also brought great trouble and helplessness to the enterprise. Therefore, in China, large capacitor manufacturers such as Jianghai, Farah, and VTCO have also increased the research and development of film capacitors.

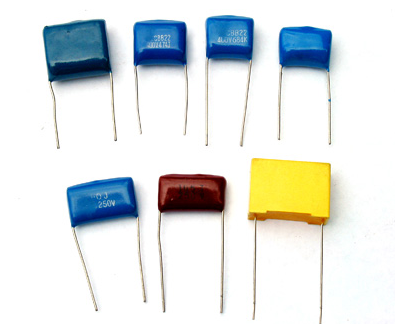

Because of the excellent characteristics of film capacitors, they are widely used in electronic circuits. According to the different requirements of different electronic circuits, film capacitors with different characteristics can be used to meet the requirements.

Due to the extremely high performance requirements of the capacitor, the most common polyester capacitor in the film capacitor seems to be unusable. In fact, it is not. In general applications, as long as the performance of the capacitor can meet the requirements, any dielectric capacitor can be used. They are all capacitors that are easy to buy and low in price. In general applications, the temperature coefficient of the capacitor is not very high. Therefore, the most common polyester film capacitors or ceramic capacitors can be used for the capacitors.

The general applications of film capacitors mainly include bypass, filtering, sample and hold, oscillation, timing and delay, calculus, audio circuits, and suppression of electromagnetic interference.